-

-

Search our Marketplace

-

- Manufacturing

- Industries

-

Materials

Not sure what material to choose? View 3D Materials Guide

- ABOUT

- Investors Marketplace

- Get a Quote

-

-

0

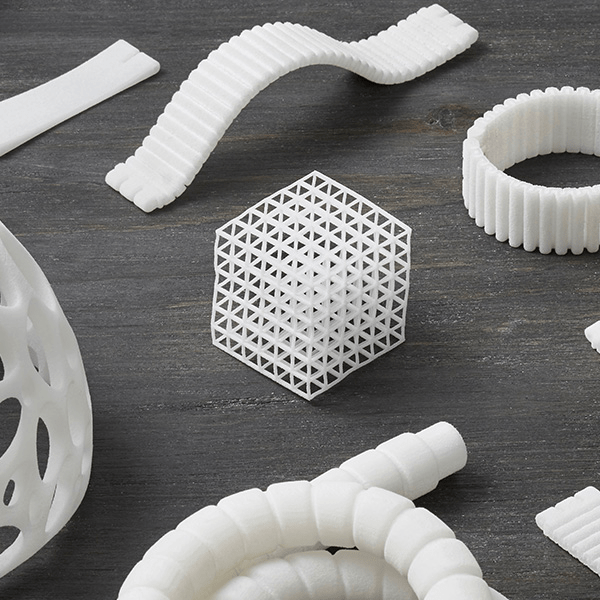

Thermoplastic Elastomer, or TPE, is an industry-standard flexible, rubber-like polymer material that is great for elastic end-use products. Printed using Selective Laser Sintering (SLS), a robust process that solidifies material layer-by-layer, TPE (SLS) parts are durable with high rebound properties and can include interlocking features. The material is skin contact safe with cytotoxicity (ISO 10993-5) and skin irritation and sensitization (ISO 10995-10) certifications. If interested in our Smooth finish for this material reach out to our sales team.

White

White

Black

Black

Maximum Bounding Box

190 × 190 × 290 mm

Minimum Bounding Box

X + Y + Z ≥ 15 mm

The bounding box is a 3D imaginary outline of a box that encloses the smallest area occupied by your model. Your model must be within the minimum and maximum bounding box sizes. If the size of the model is close to the maximum bounding box, then the printing orientation will be restricted.

A supported wall is connected at least on two sides of the wall, while an unsupported wall is connected only on one side of the wall. Walls that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wall geometry of the model. Please consider the size of your model and reinforce the walls or add support structures as needed as minimum guidelines will not always be adequate for large models.

1.0 mm (Natural & Smooth)

1.0 mm (Natural & Smooth)

A wire is a circular, rectangular or even triangular feature that is thinner in its unconnected directions than its length. A supported wire is connected at least on two sides of the model, while an unsupported wire is connected on one side of the model. Wires that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wire geometry of the model. Please consider the size of your model and reinforce the wires or add support structures as needed as minimum guidelines will not always be adequate for large models.

0.8 mm high & wide (Natural & Smooth)

0.8 mm high & wide (Natural & Smooth)

For text, the ratio between width and depth, should be 1:1 and sans-serif fonts are preferred for line weight consistency.

5.0 mm (Natural & Smooth)

5.0 mm (Natural & Smooth)

Escape holes are necessary to empty the support material of a hollow model. Two escape holes at the opposite ends of the model is optimal for the support removal process. Please consider the size of your model and make the escape holes bigger or add more escape holes as needed as minimum guidelines will not always be adequate for large models.

2.0 mm (Natural & Smooth)

Clearance is the space between two individual parts in a model. If the space among the individual parts do not meet the minimum clearance, then parts can fuse together or can be difficult to clean. This is important for movable pieces like hinges, gears, etc.

Interlocking

Yes

Enclosed

Yes

Up to 250 (Natural)

Up to 10 (Smooth)

± 0.25 mm , then ± 0.5% of longest axis

From product development to industrial 3D manufacturing, we can help you scale your business.

contact sales